SPRAY NOZZLES FOR

THE PETROLEUM & PETROCHEMICAL INDUSTRIES

BETE is a trusted international spray technology supplier for many corporations in the petroleum & petrochemical industries.

BETE’s extensive catalog of standard nozzles meets the requirements of many applications, while custom development is available for specific customer needs. Our spray nozzle technology offers first-in-class in reliability & durability for the harsh environments found in refineries.

We offer a wide range of nozzles in durable materials ideal for crude oil, abrasive media, corrosive reagents, extreme temperatures, or all of the above. That’s why top oil & gas companies rely on BETE to supply them with mission-critical spray nozzles, injectors, lances, and spraying systems.

Common Applications

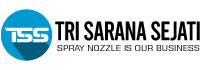

- Inject various reactants, scavengers, inhibitors, or other chemicals throughout many processes.

- Use water wash injection nozzles at various points in refining crude oil into its component fractions.

- BETE can design a custom injection lance specific to your application, ensuring proper fabrication, installation, and operation.

BETE spray nozzles maximize efficiency in inhibitor injection applications as they atomize and distribute the inhibitor liquid into the vessel or process stream. Compared to open-ended injection quills, these specialized spray patterns improve the coverage and reaction with chemicals and compounds that may cause corrosion or scale formation.

- Scrubber nozzles remove pollutants and other chemical contaminants from process gasses, liquids, and equipment.

- Scrubbers also remove acids from chemical processing off-gasses.

- BETE offers nozzles for a wide variety of scrubbing systems.

- Open Towers

- Packed Towers

- Venturi Scrubbers

- NOX Removal (SCR/SNCR)

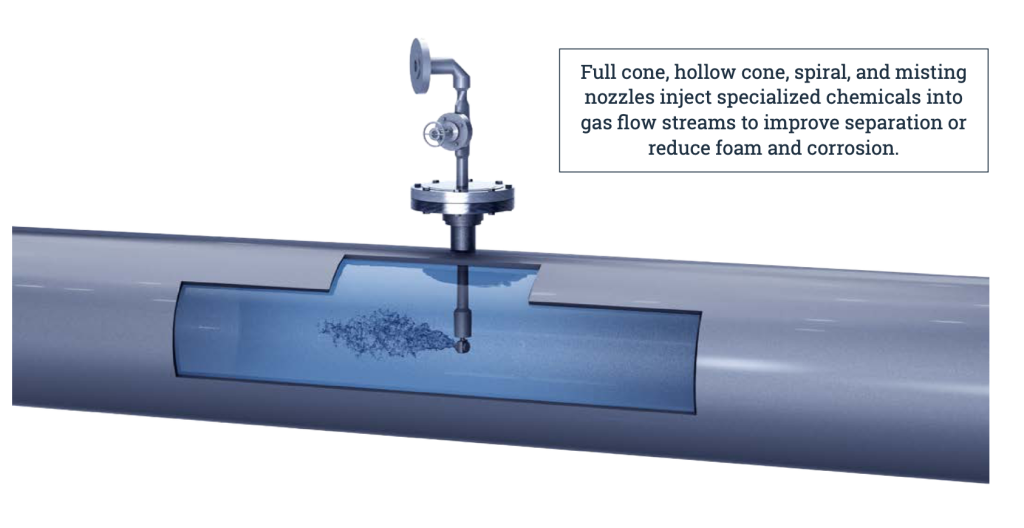

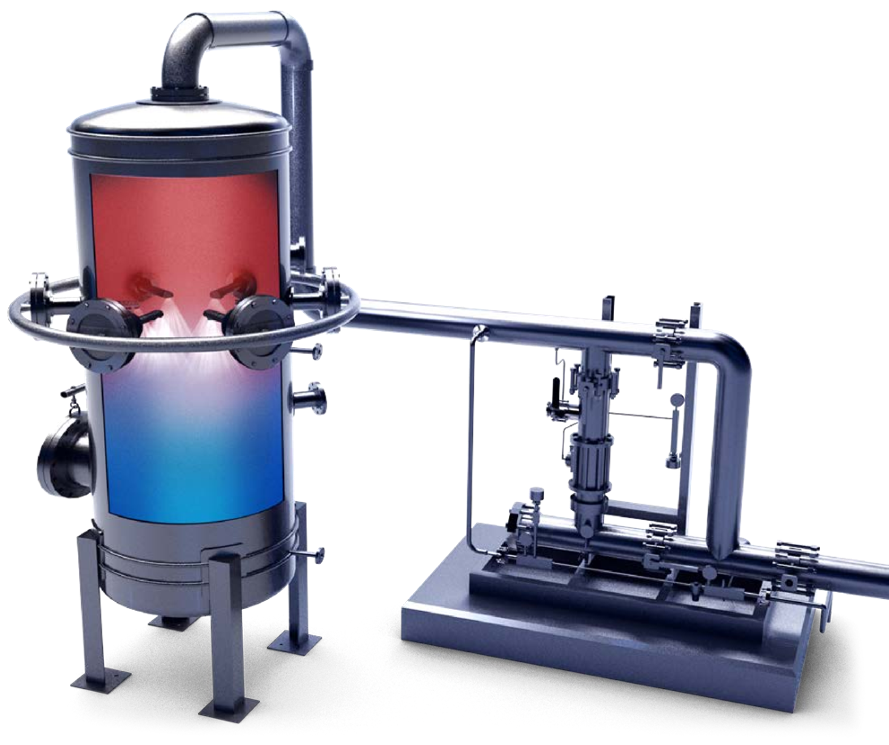

- Nozzles for gas cooling or quenching in various petrochemical applications create stable conditions for downstream plant components’ safe and efficient operation.

-

- Cooling process gases prior to scrubber/baghouses

- Catalyst reformer gas cooling

- Cooling combustion exhaust gases

- FGD quenching

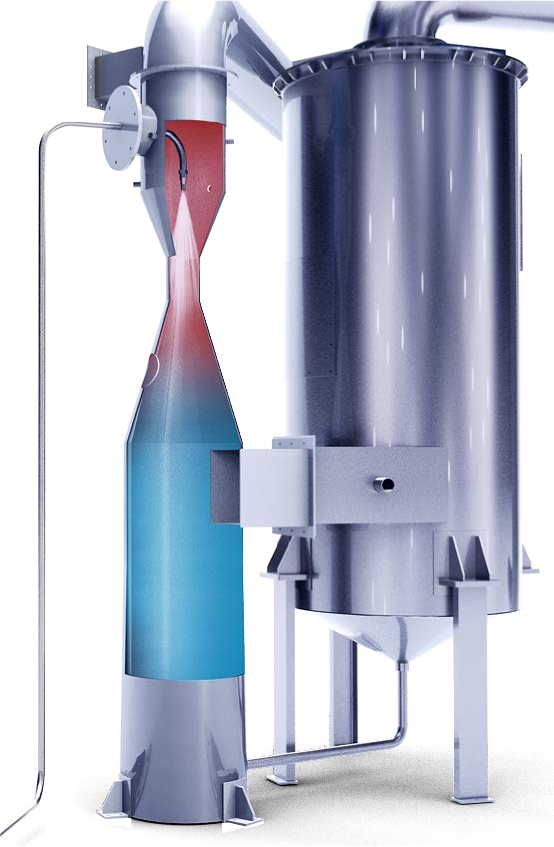

- Tank cleaning is essential, especially when removing harsh chemicals and soils, which can be time-consuming and expensive without the correct solution.

- Optimize cleaning with BETE’s stationary, free-spinning rotational, and controlled rotational tank cleaning nozzles in the refining process:

-

- Rail Cars

- Storage Tanks

- Reactors

- Process Vessels